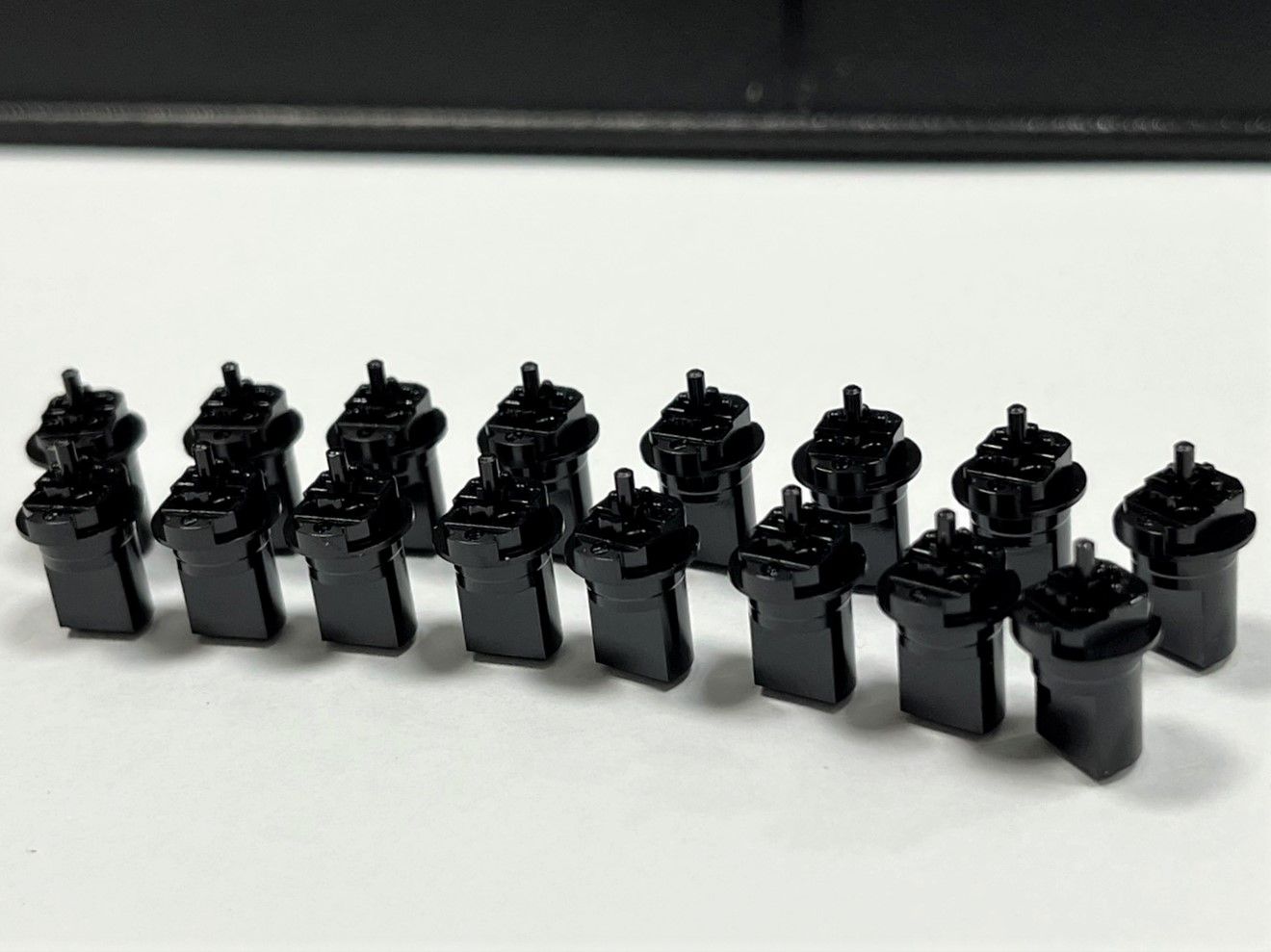

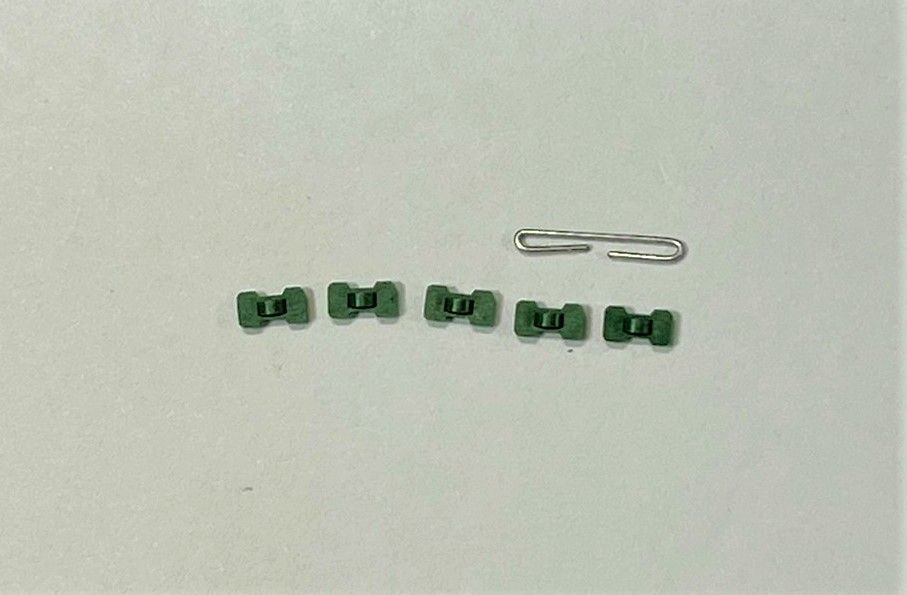

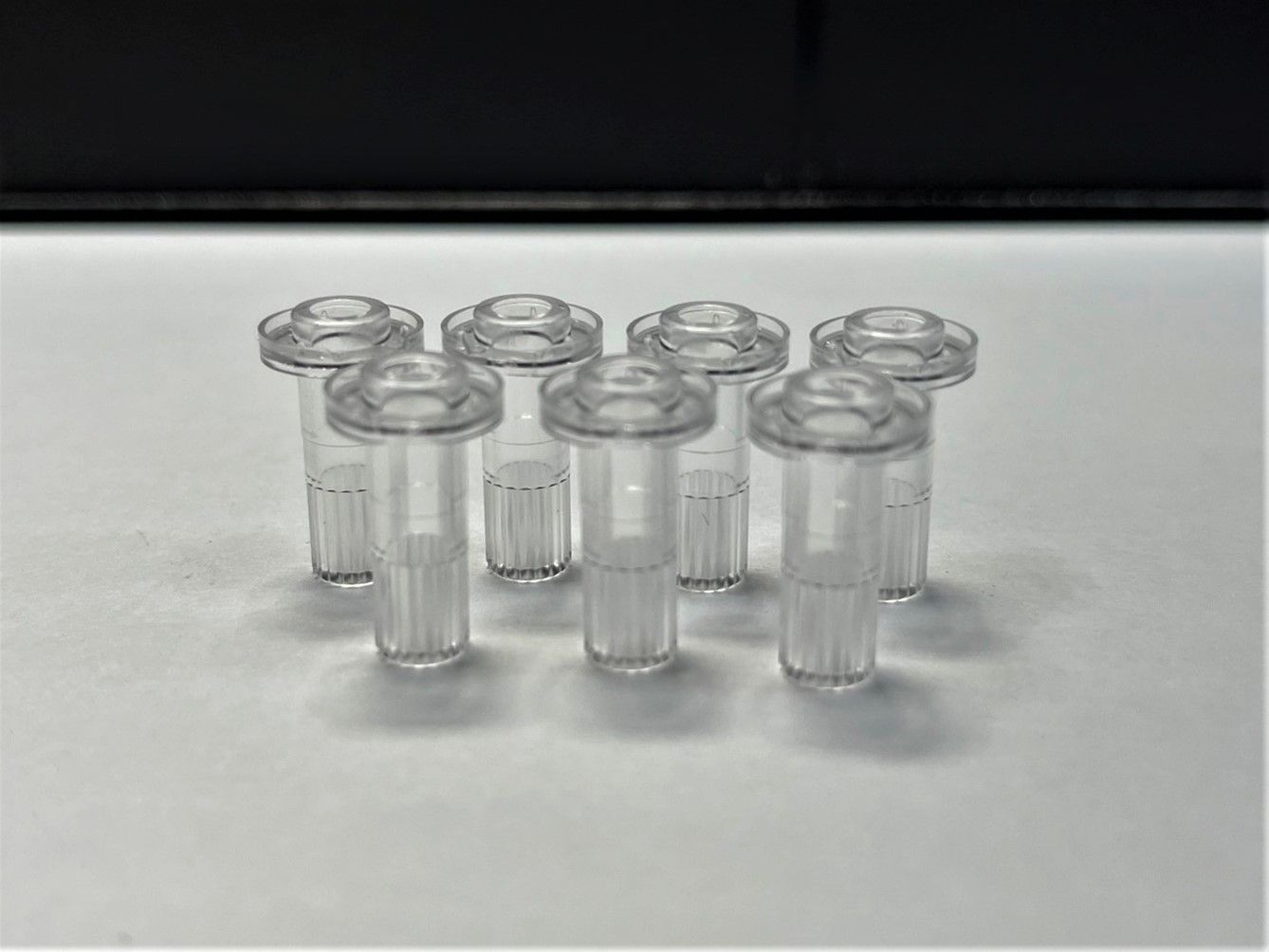

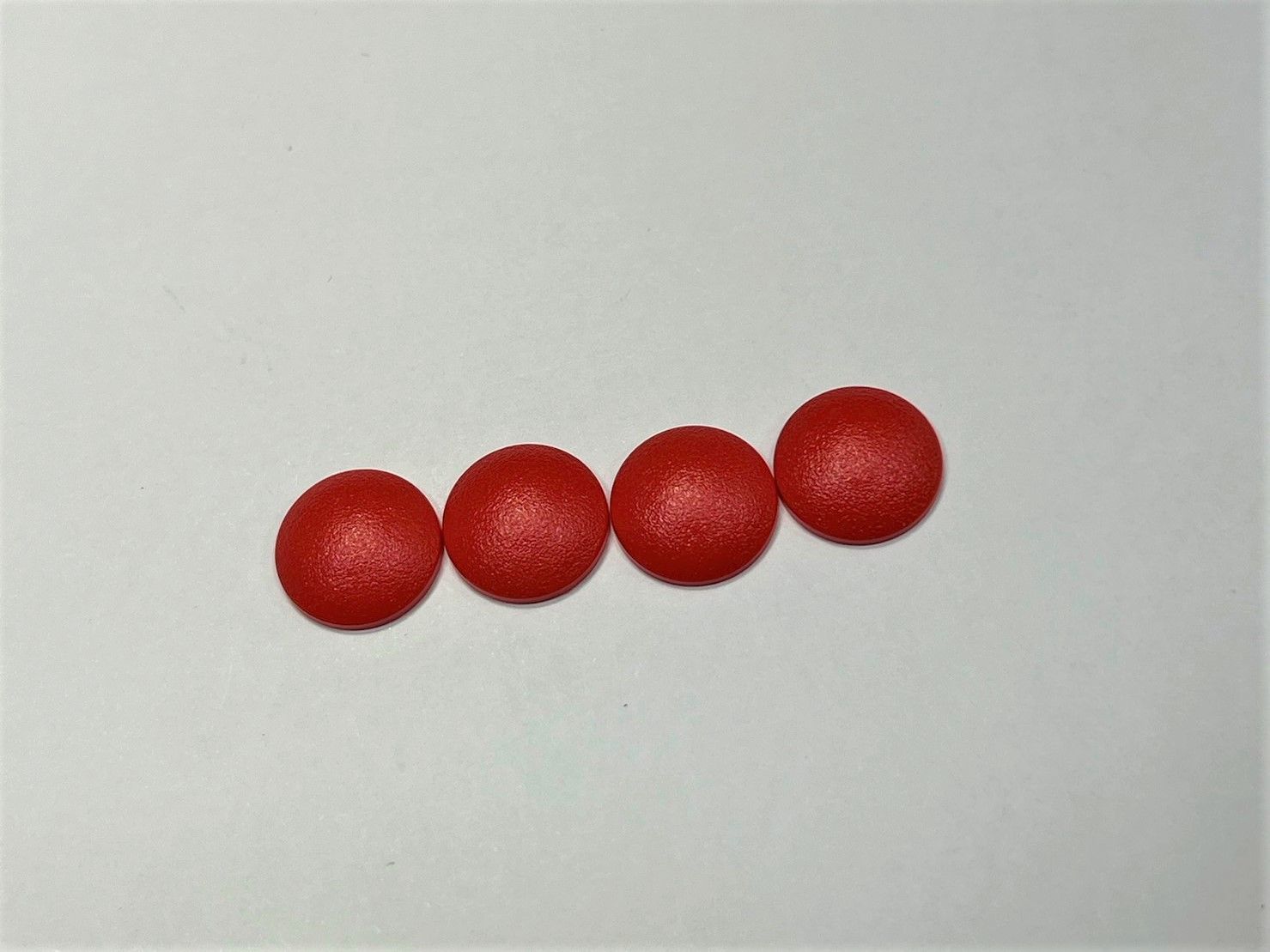

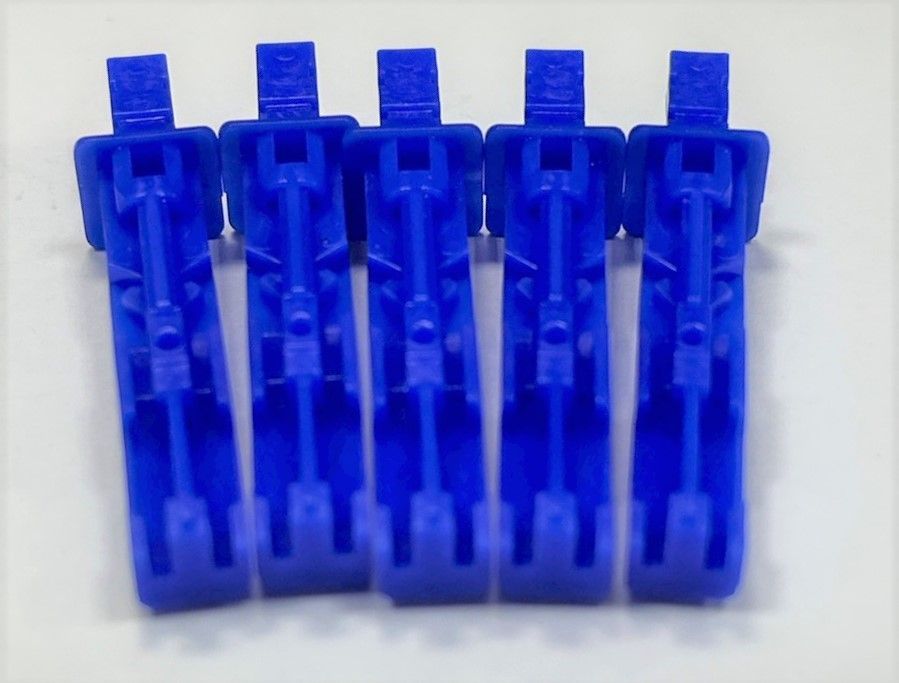

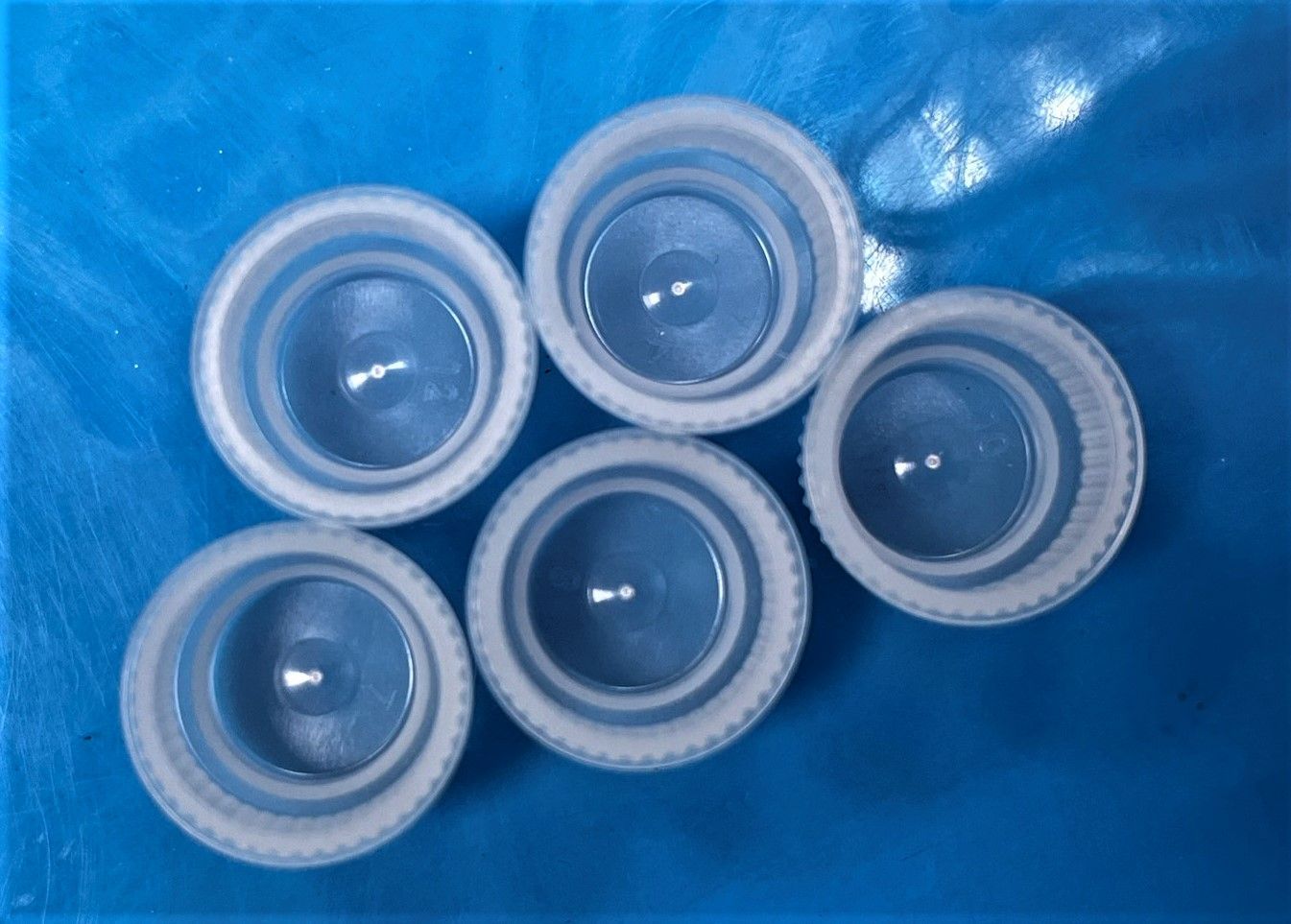

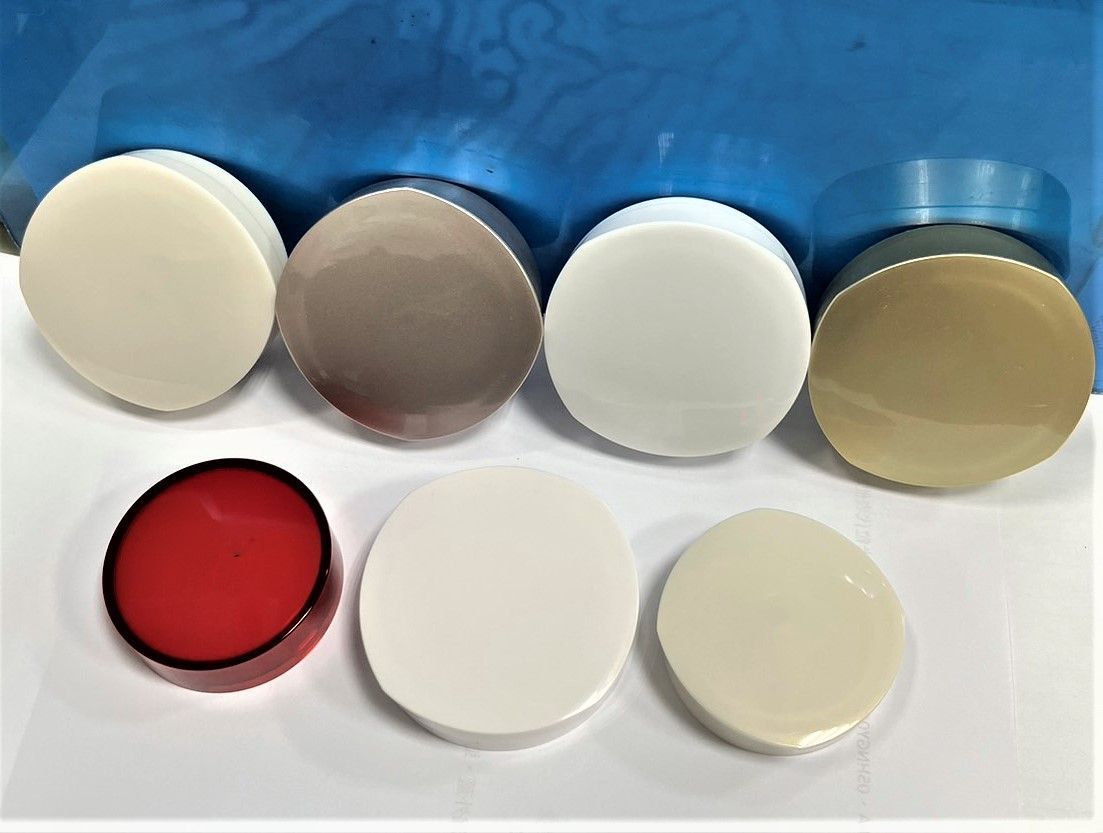

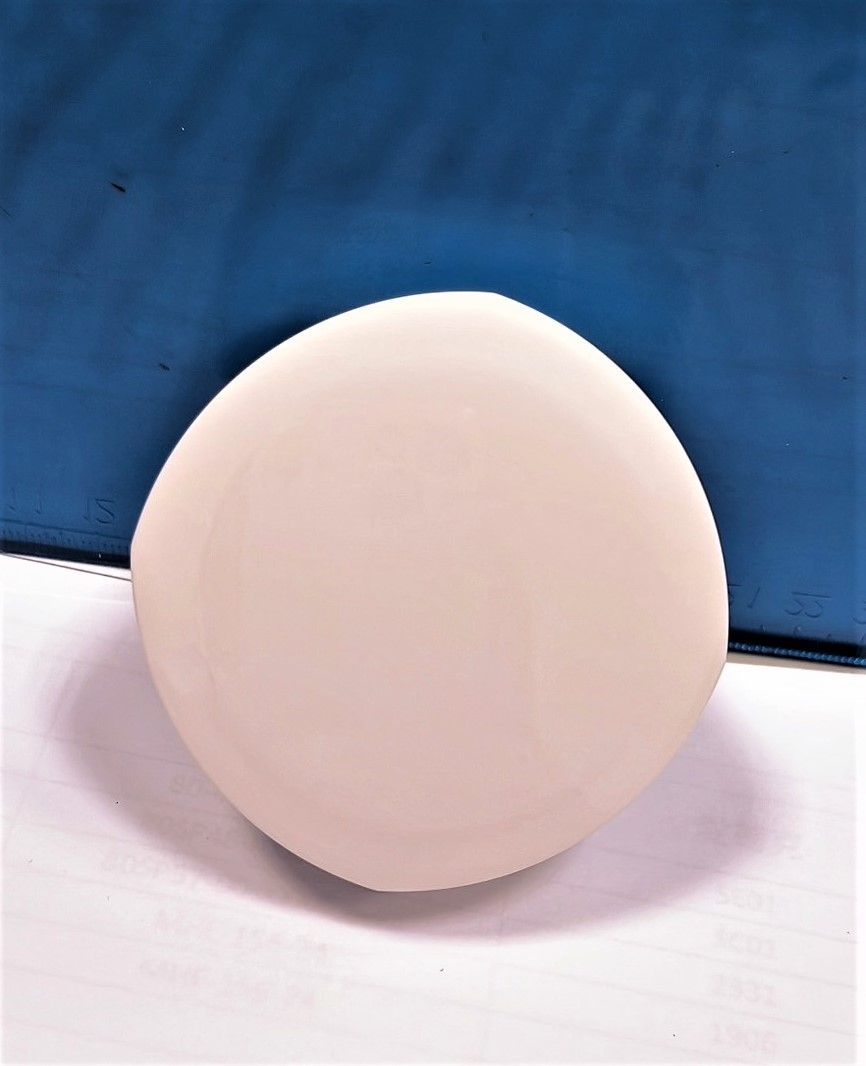

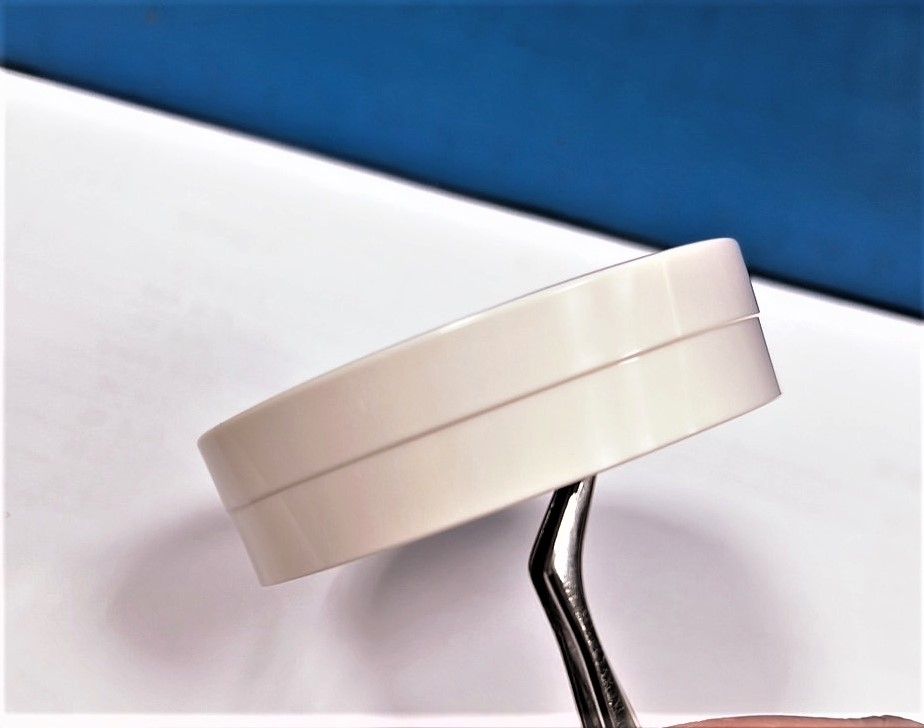

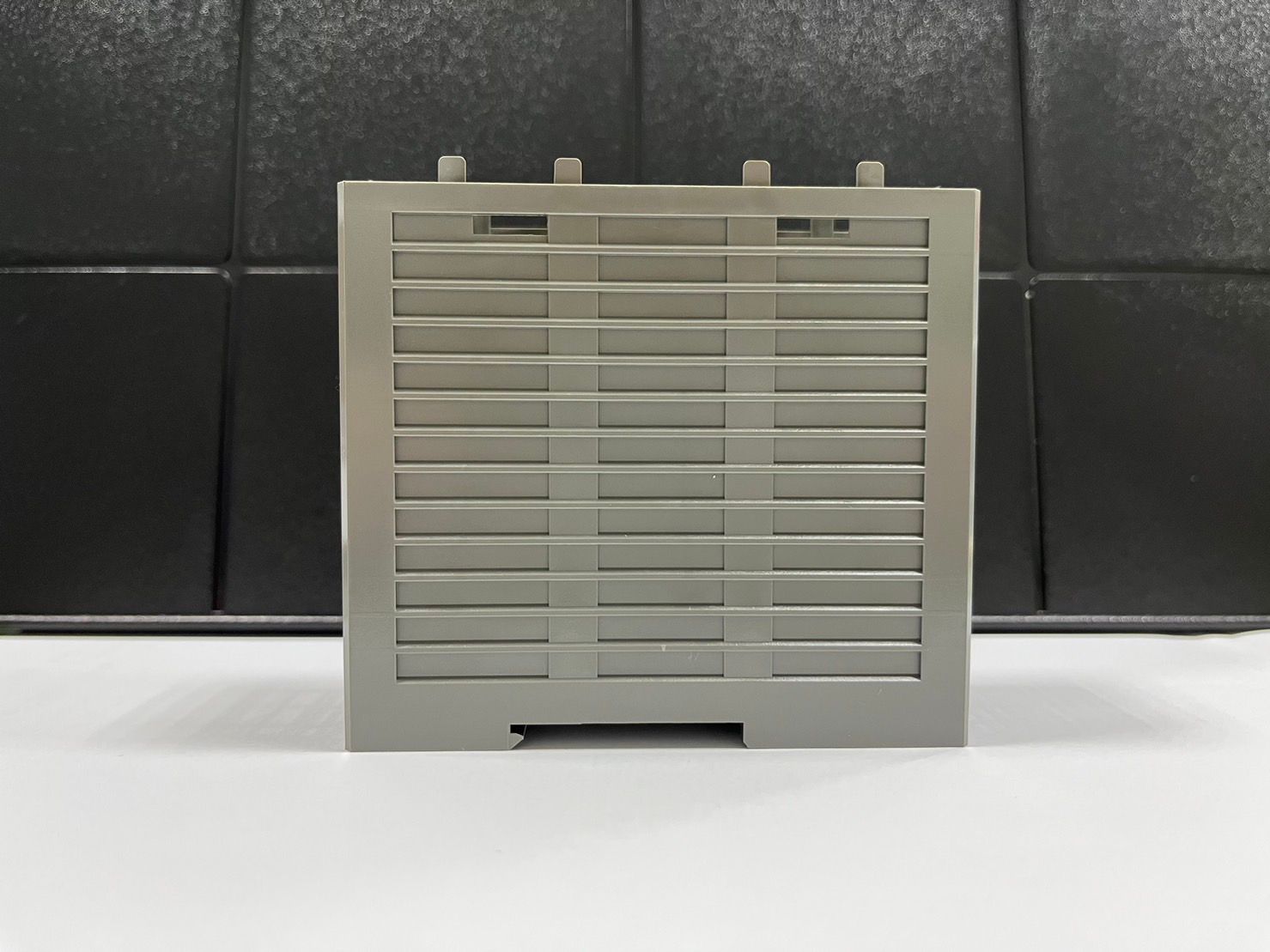

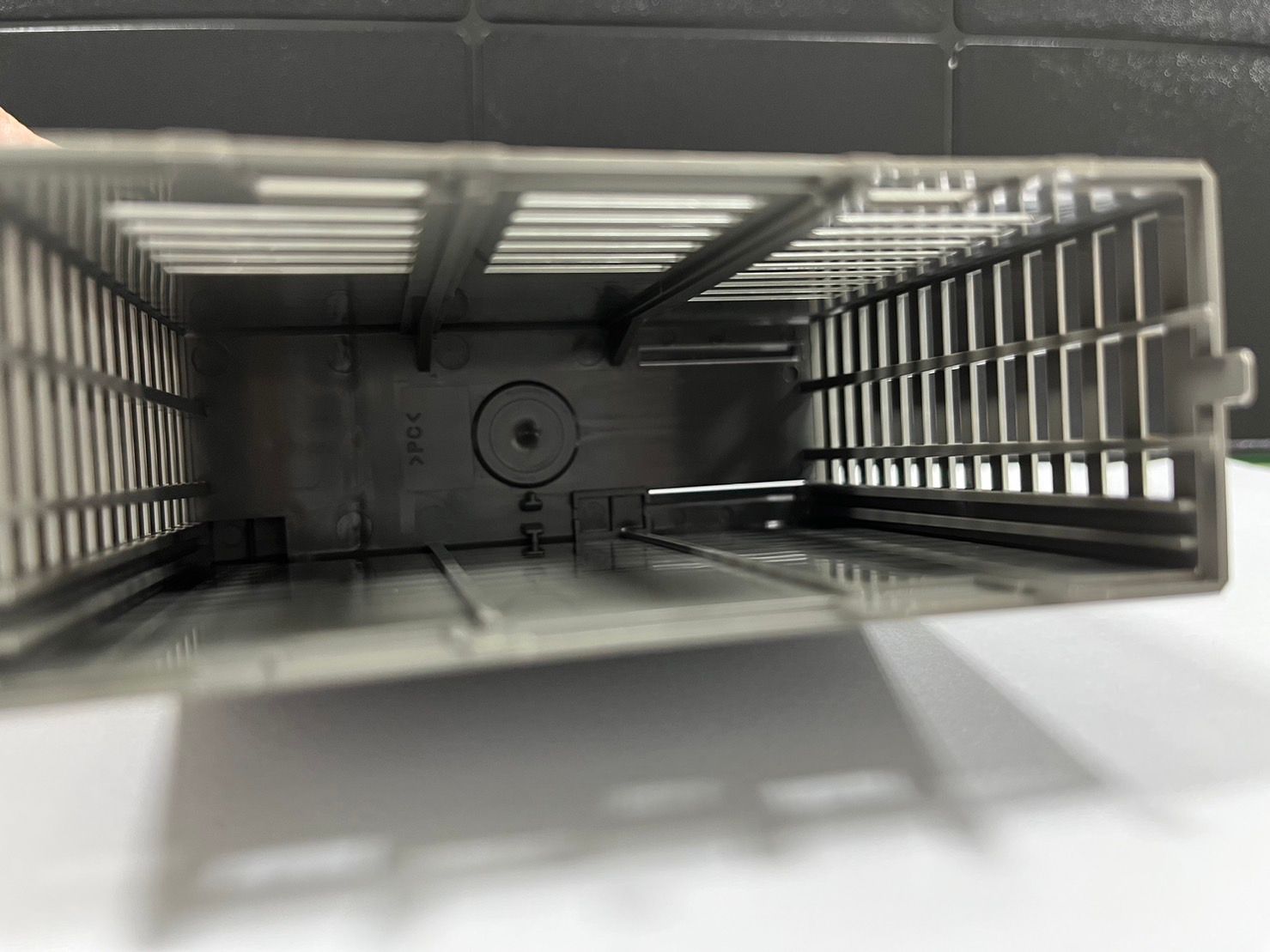

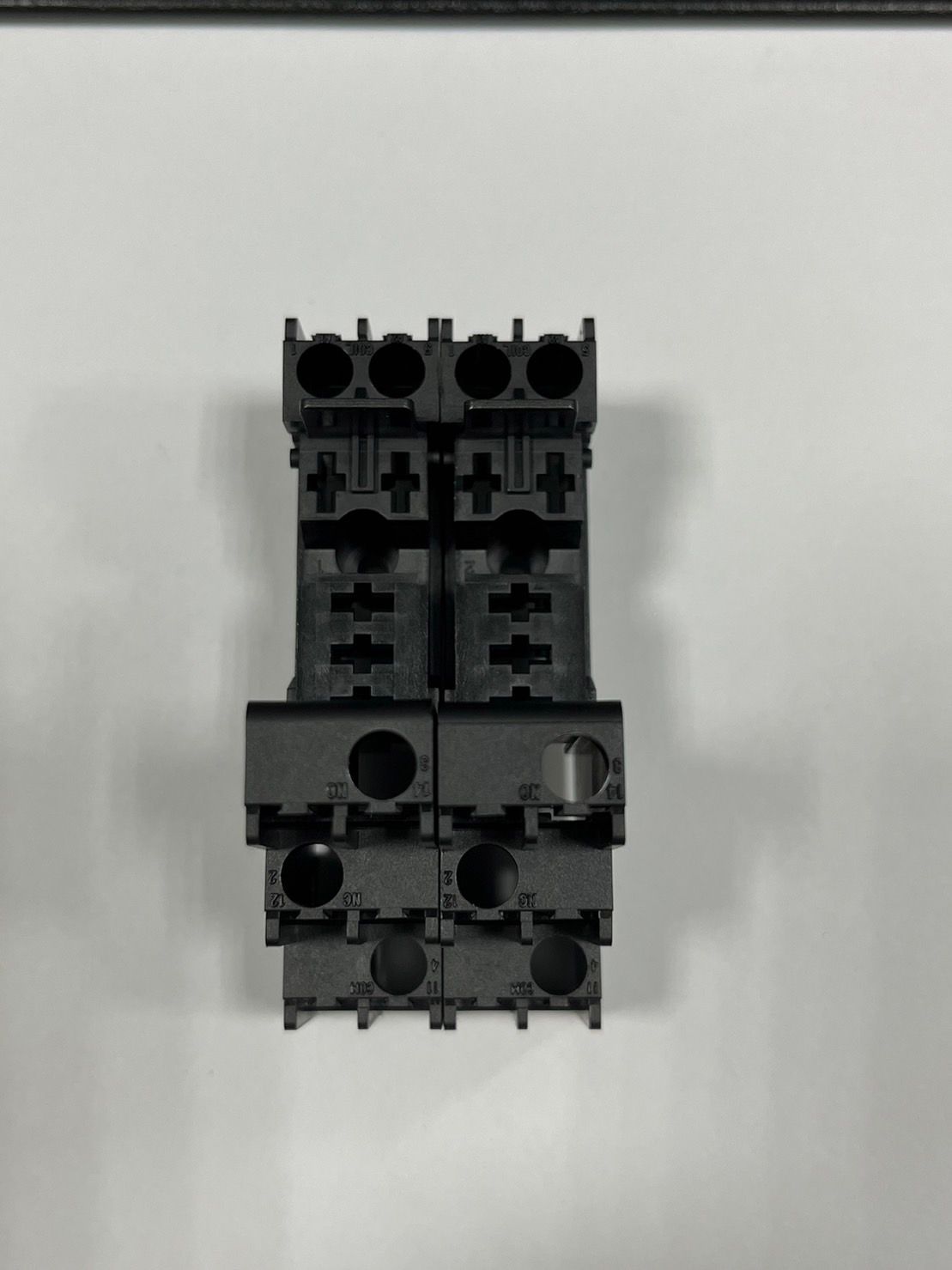

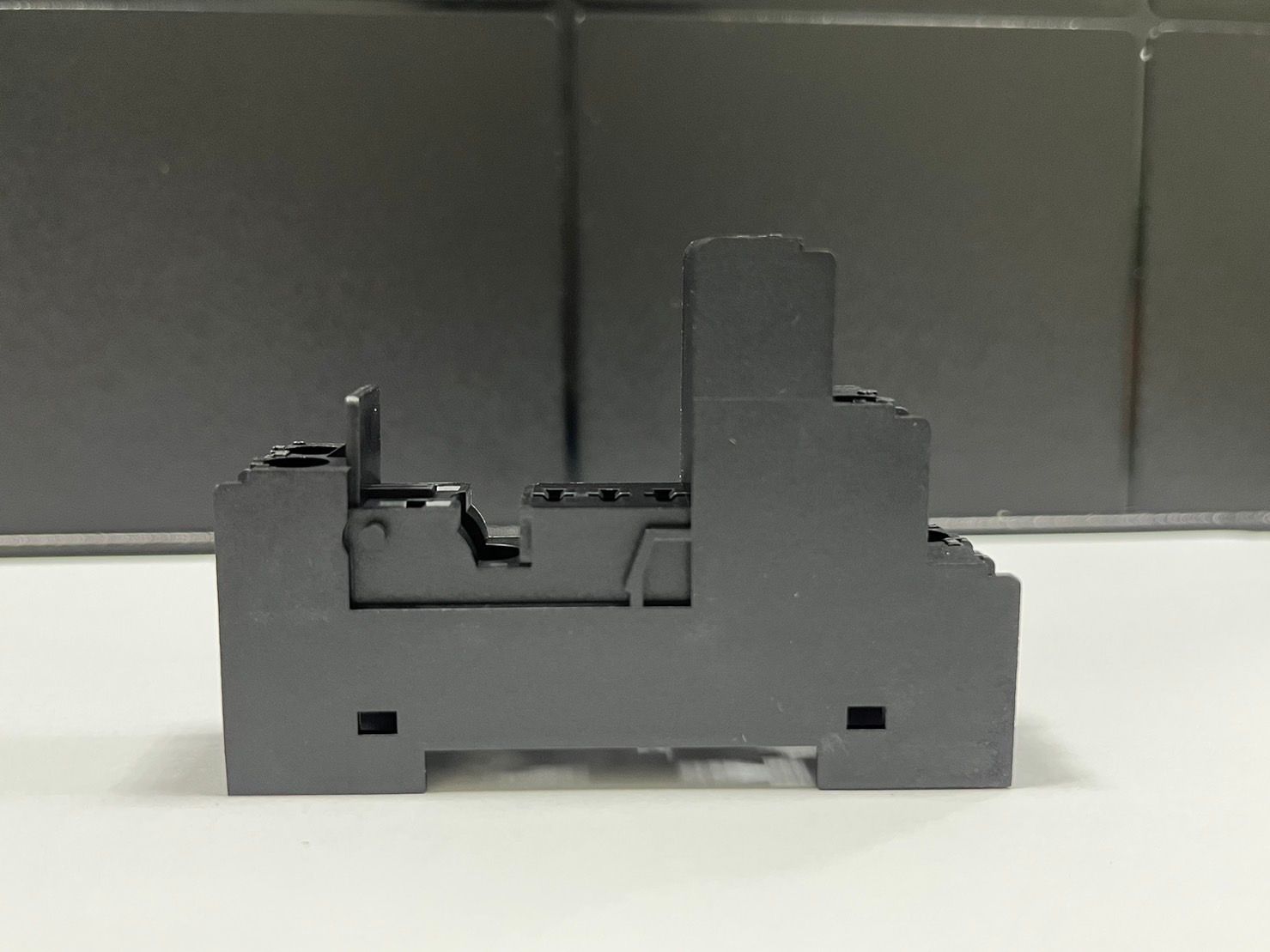

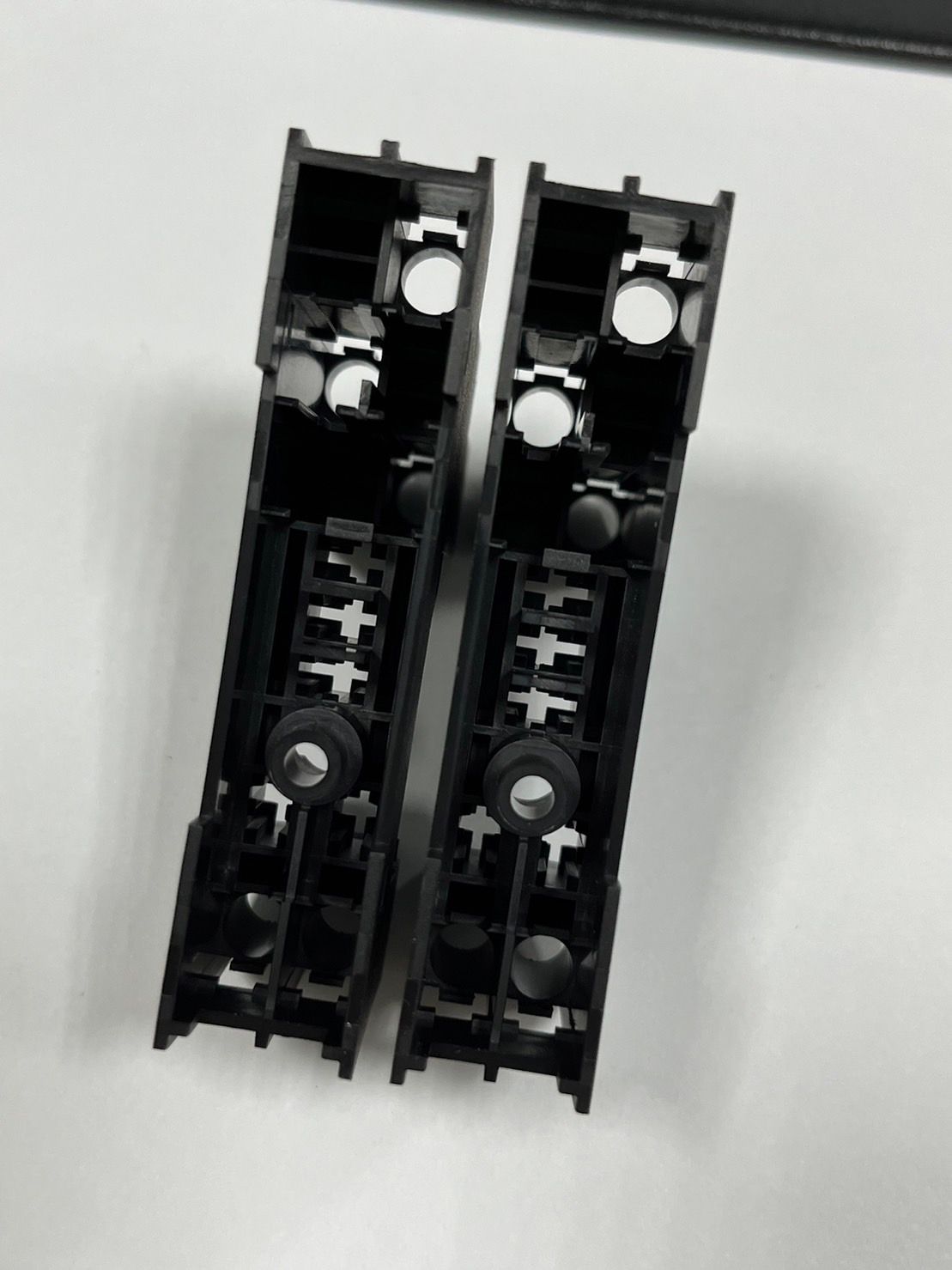

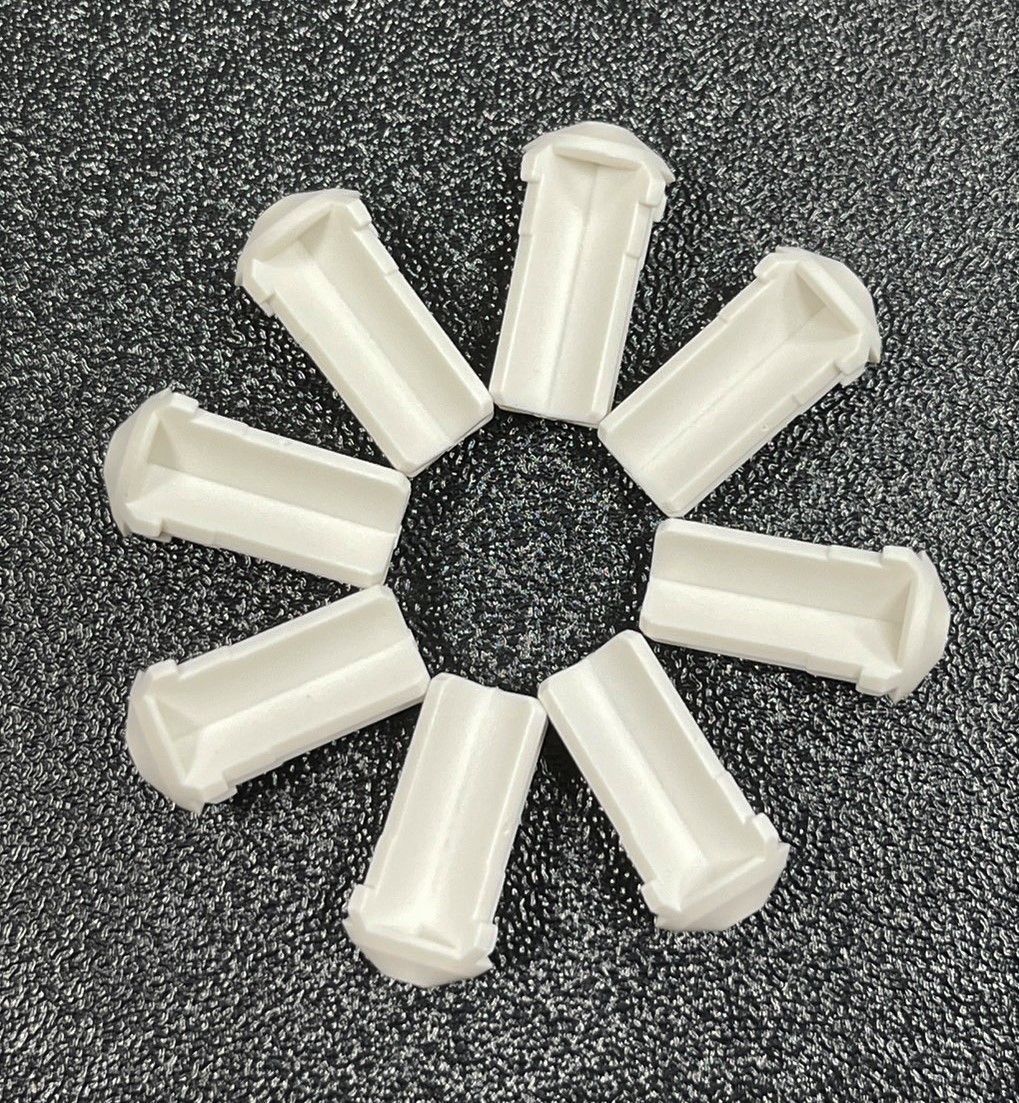

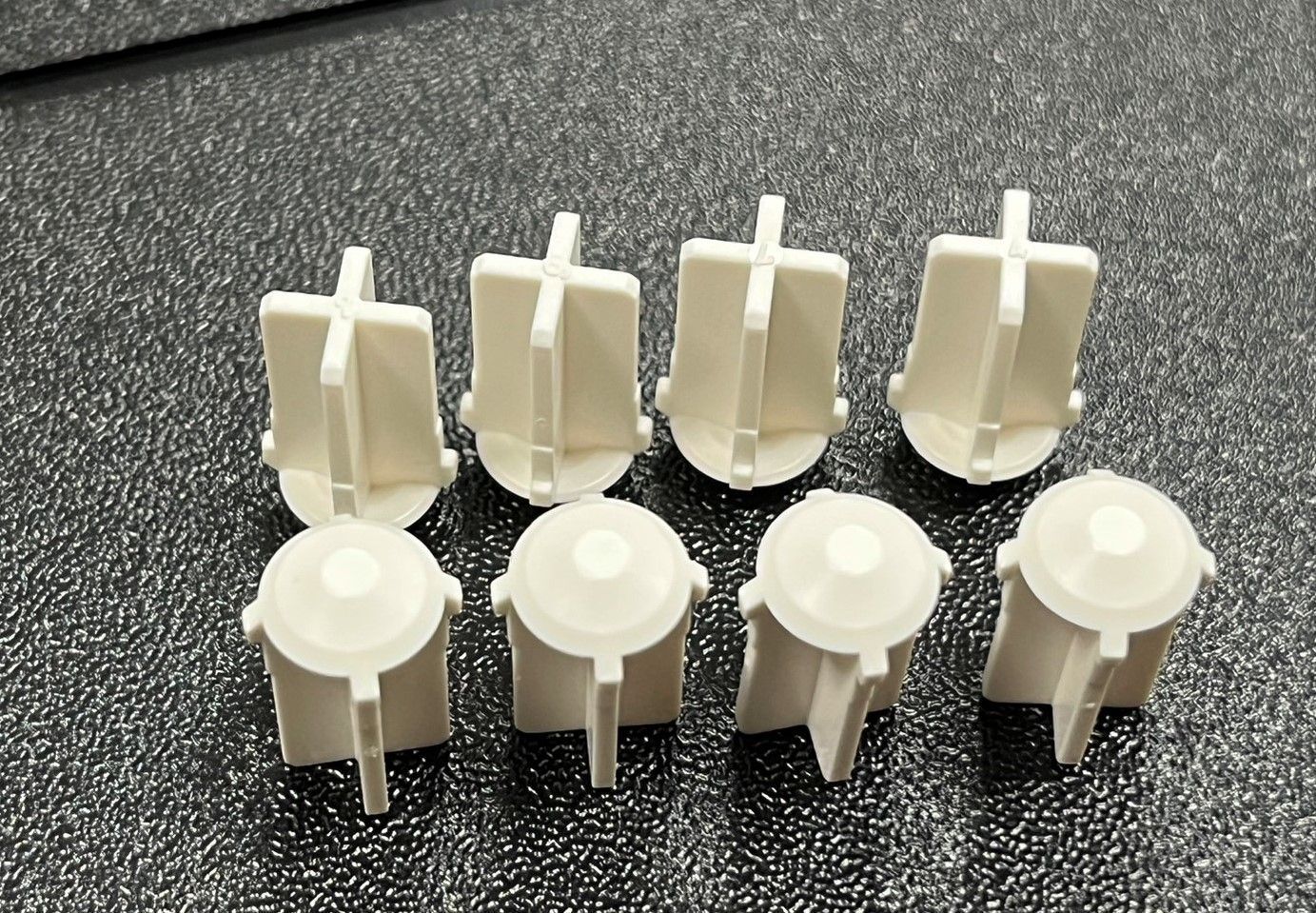

Injection molding

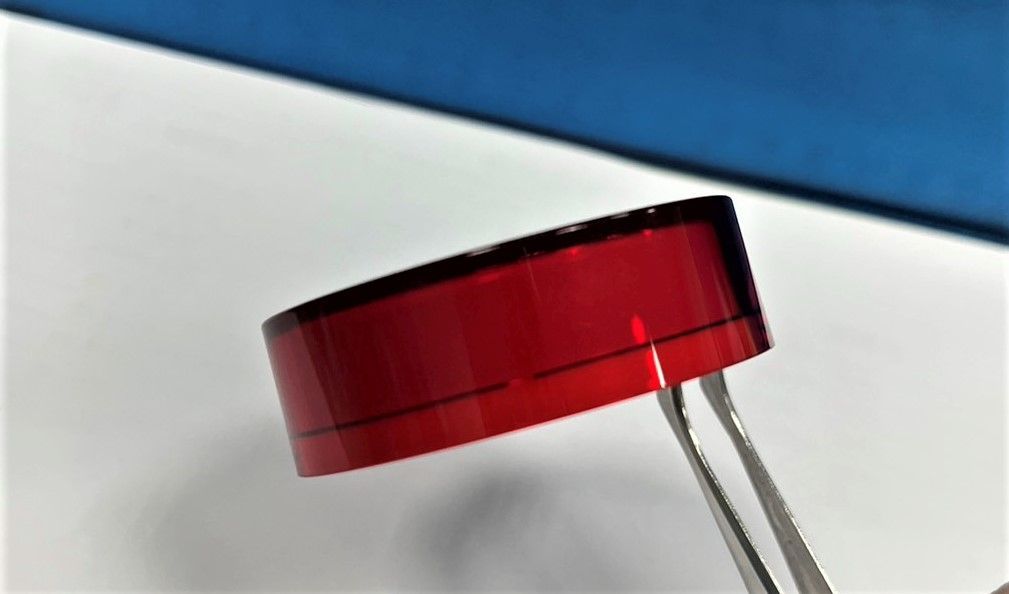

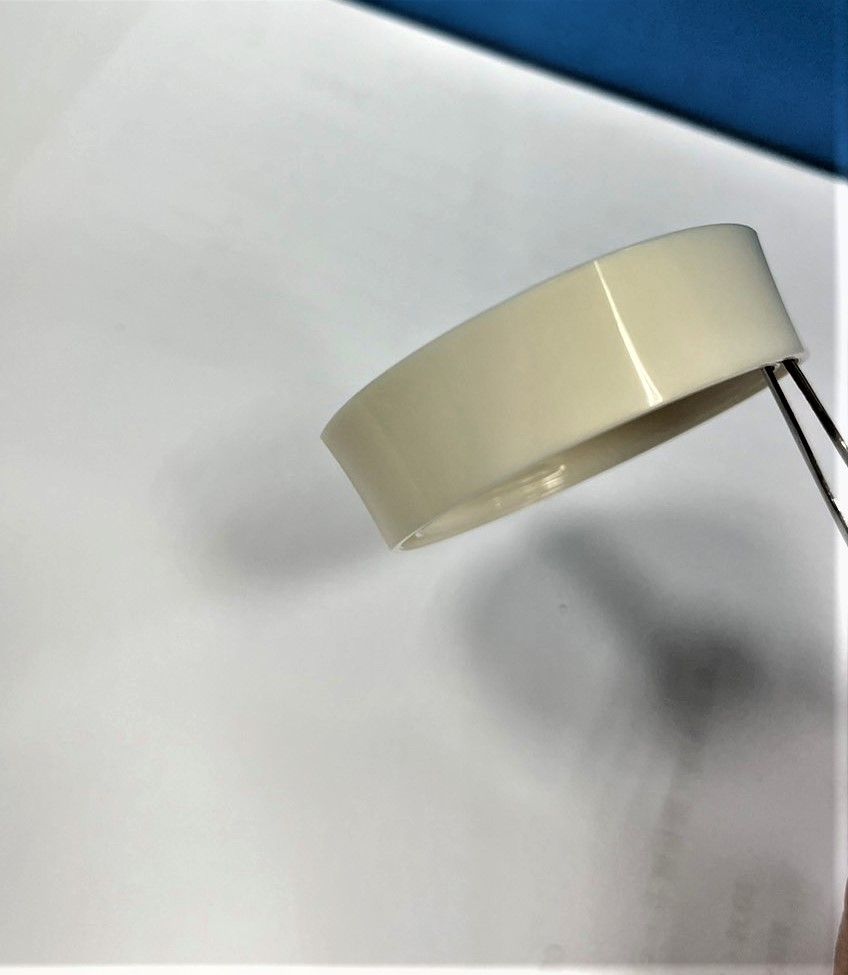

Injection molding conditions are unpredictable. It is actually not easy to optimize production through parameters such as temperature, pressure, speed, time, etc. The stability of the machine, the temperature and humidity of the environment, the stability of the mold, and the stability of the material will greatly affect the quality of the product. Based on the first four points, we set the control focus of each link, the stability of the machine (end injection position, plasticization time), the temperature and humidity of the environment (humidity and temperature monitoring), and the stability of the mold (Inspection of key mold dimensions before and after production), material stability (control of the proportion of new and inferior materials, moisture content), and subsequent auxiliary inspections of the quality control system (FAI, sampling plan), to try to make the quality meet customer needs.

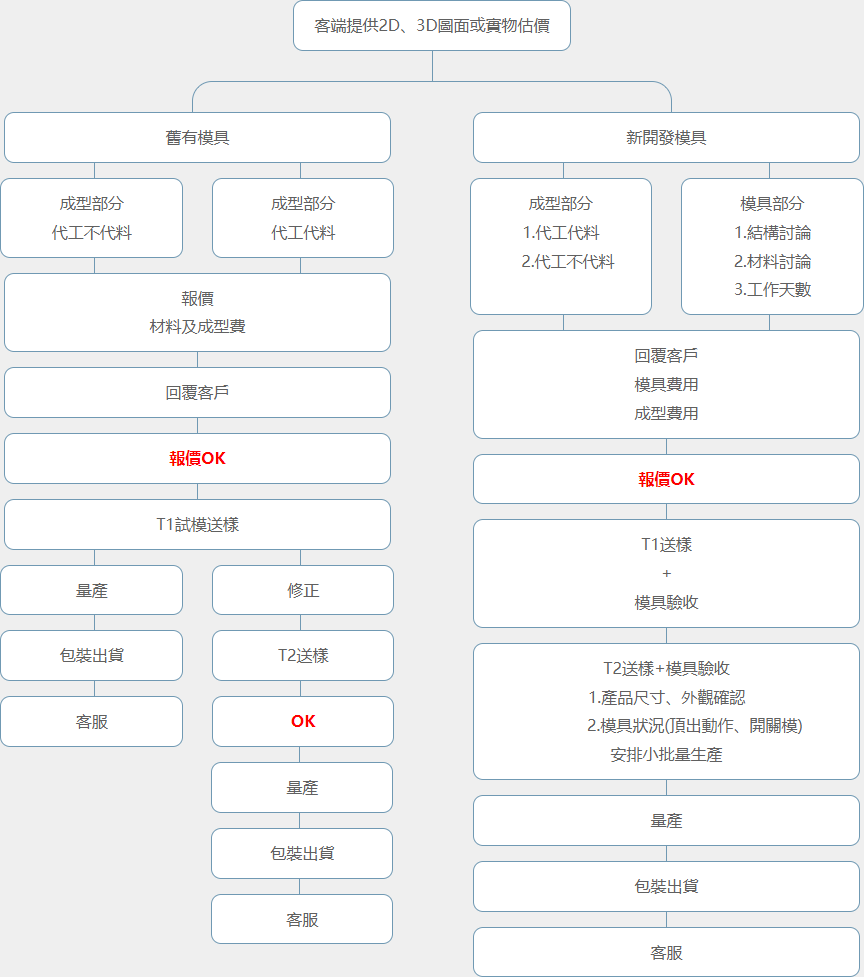

Service content